Print House

Print house in Marko-Kolor is operating since April 2008. We’re printing with a use of a modern, 8 color rotary type printing machine from Reggiani.

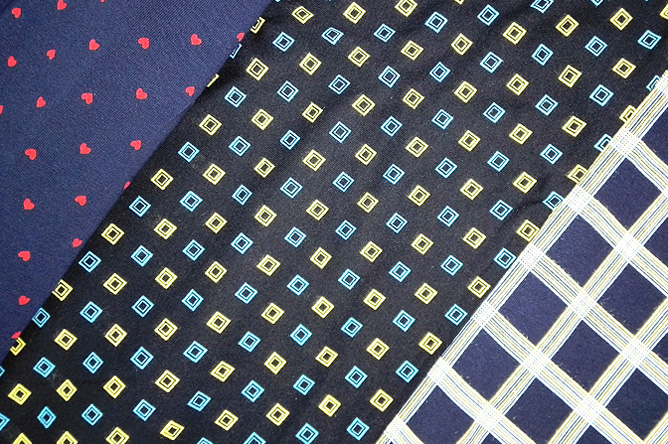

We’re printing on woven and knitted fabrics composed from cotton, viscose, polyester and its blends. Depending on the demands from our customers, we suggest application of pigment, reactive and disperse print.

In short, we would like to present printing technologies which we use.

It is the most common of printing technologies, suitable for almost all textile garments from wovens for jackets to knits for children confection. Pigments and agents of our use guarantee very high usable properties and acquisition of safety attests. Application of pigment print is relatively cheap and gives vivid and clear colors.

Used mostly for printing of viscose for summer blouses and dresses. This kind of print is characterised by nice and soft touch and very high fastness of rubbing and washing. It is a slight more expensive technology and a bit more complicated from the technological point of view.

Used only for knitted and woven fabrics composed from polyester, because of the nature of the fibers. It gives very permanent and soft in touch prints with unlimited color range.

Plain and one color surfaces is classic, slightly boring, a little bit out of the fashion. We like it because it is safe. Fashion is closing the circle, we are coming back to the old methods of refinement of knitted and woven fabrics giving them new look.

Fashion and with it technique and technology are seeking for newness and new expression for new times. People do not want to look the same, as they were wearing the same clothes. That is why we’re looking for new ways of standing out, changing our image.

Clothing is the best way for image change and to stand out from the crowd. For ages, people invented different ways of dyeing, refining and changing the look of fabrics. Tye-dye, ice-dye, batik, shibori… various methods making fabrics look different and individual. Attempts of brightening jeans by the use of basic bleaching resources were and are practiced by home creators. Jeans is a brilliant invention of world of fashion which can be used in various stylizations. Currently new technological methods were developed allowing for more professional obtaining of interesting and original effect.

Reserve print is a technique perfectly suitable for jeans look fabrics, which allows for creation of new effects. Pattern is applied on raw fabric which in next step is treated with processes of finishing. Dyeing of such fabrics is realized with a use of most modern technology KKV, which is cold pad batch dyeing with the lowest influence on environment.

Innovation from the last seasons is discharge print. Both of techniques allow for precise transfer of patterns and obtaining attractive designs. Effects on different backgrounds and colors can be astonishing, because printing and dyeing are made on checked recipes which give us new, interesting look, which is important in fashion.

Discharge print technique is not based on application of printing paint on the surface of the fabric, but on application of agent which “gets out” the color from the fabric. Fabric parameters are not changed, touch is nice and soft and elasticity is maintained. This kind of technique works out perfectly with dark backgrounds and it gives the most spectacular look on denim type fabrics, creating interesting designs.

Surprising how many effects can be achieved with a use of reserve and discharge print. Designers imagination allows for creating new design and gives new face, new life of well known fabrics.

If you are interested in achieving such effects on your products please contact us by phone 696 030 690 or 795 501 085 or email: drukarnia@marko-kolor.pl